Paragon has developed unique solutions for the obsolete Union Carbide high flux isotope reactor (HIFR) controls.

The magnet amplifier is normally used to control the current to a SCRAM latch magnet in the reactor safety system. Paragon’s approach to reverse engineering provides a replacement analog solution that uses new component technologies. The large component original discrete system that was comprised of transistors, power resistors, and wiring to perform a feedback loop automatic gain function, was replaced by small printed circuit boards with surface mount operational amplifiers. Additionally, the housing is redesigned to a more rugged structure with more robust cooling. The result is a new unit with modern parts that maintain the analog nature and functionality with a more reliable design.

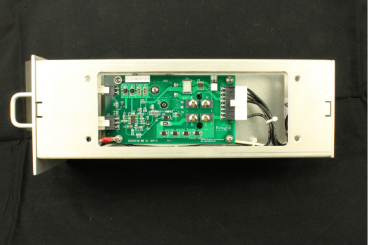

The flux signal conditioner is used to take the core power measurements from the rapid monitoring, but inaccurate, ionization chamber flux, and the slow moving, but highly accurate, heat power monitoring to provide a signal that has the accuracy and speed of both. Paragon’s approach to the reverse engineering provides a replacement solution that is part by part equivalent, replacing each through-hole component with an equivalent surface-mount component with equal to or better ratings than the originals. Additionally, the housing is redesigned to a more rugged structure and test points were added to assist in-system calibrations. The result is a new unit with modern parts that maintains the same analog schematic with a more reliable design.

Part Numbers

The part numbers below have been reverse engineered by Paragon and are available for manufacture. Click on each part number to link to the Paragon Catalog.

Part Number |

Description |

|---|---|

| Q-2613-1/ATC | Magnetic Amplifier |

| RC11-19-1/ATC | Flux Signal Conditioner |