The obsolescence of analog I&C systems is one of the nuclear industry’s greatest challenges today – and Paragon is the solution.

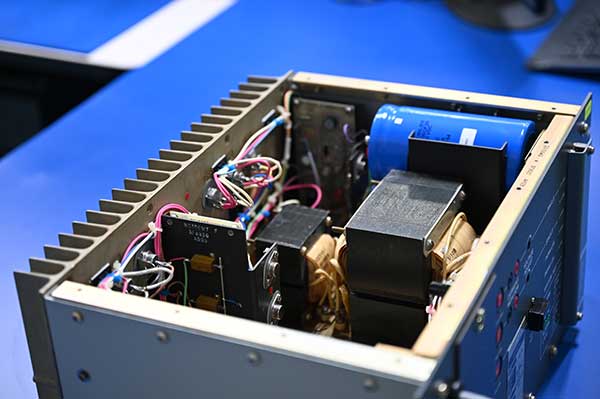

For over thirty years, Paragon has kept these obsolete systems functioning and even extended their life cycle through repair and reverse engineering. One such system is the Foxboro SPEC 200.

Our Expertise

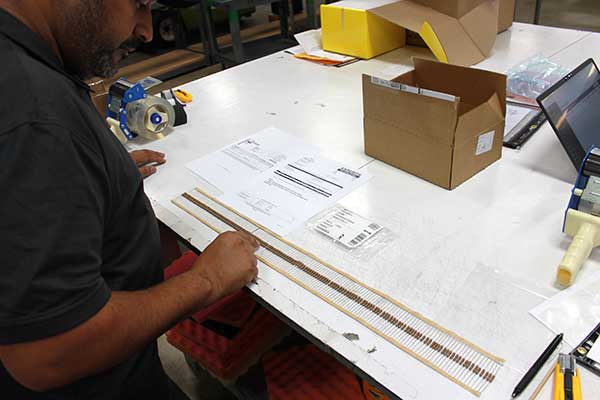

The technicians at Paragon have decades-long, proven expertise with analog systems, including the Foxboro SPEC 200.

Our Testing Processes

The comprehensive testing processes done in-house at Paragon exercise all inputs and outputs, ensuring that repaired items meet or exceed required specifications.

Our Facilities

Paragon’s state-of-the-art repair facility adheres to the highest standards, meeting 10 CFR-50 Appendix B and ASME NQA-1 requirements. Plus, with 24-hour emergency support, we’re ready to assist whenever you need us.

In many cases, we can re-create design information and analyze circuits to determine precise operating parameters.

So, choose Paragon…

- If you want your I&C equipment to remain reliable, efficient, and cost-effective throughout its life cycle.

- To proactively address and mitigate the challenges of I&C obsolescence.

- Whether you’re dealing with Safety-Related or Non-Safety Related SPEC 200 modules.

We’ve handled it all!

Our Typical Repair/Refurbishment Process

Paragon performs a detailed receipt inspection on customer-supplied material.

We test, troubleshoot, and identify replacement components suitable for the application. Replacement components are evaluated and inspected upon receipt.

Repairs are performed by certified IPC 7711/7721 specialists. The repairs are independently inspected to IPC 610, and customer specifications by certified IPC 610 Inspectors.

The customer-supplied item then undergoes a post repair test, burn-in, and final acceptance test.

Paragon develops innovative solutions for the nuclear industry that are safer, more reliable, and more cost-efficient.